Mach5 Tabs Gen 1

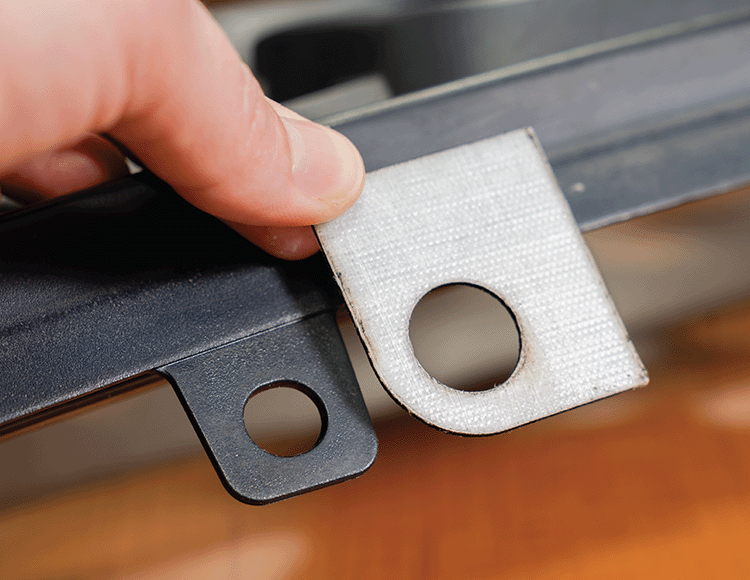

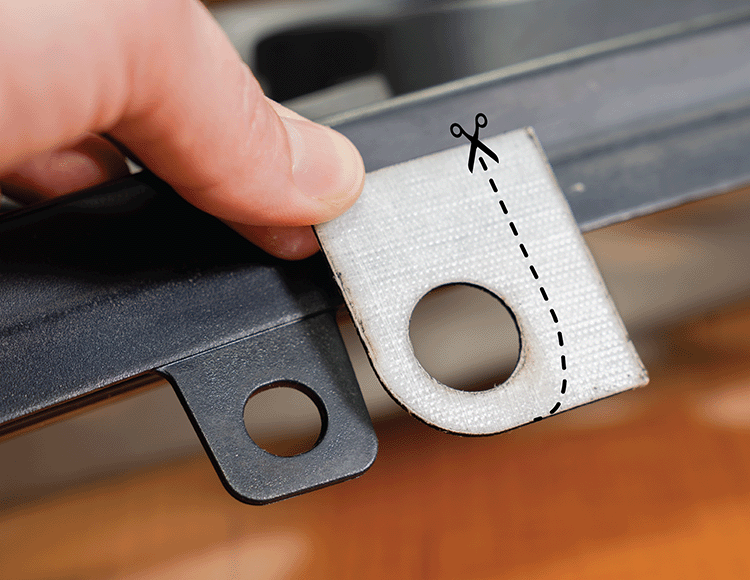

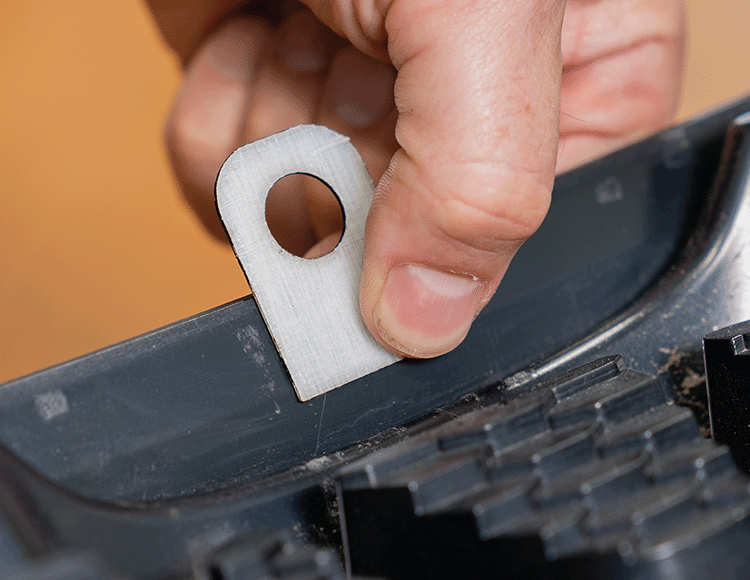

These prototypes are designed as a quick and easy repair solution for broken connection points used on car bumpers, panels, and other components. They have been designed in various shapes and sizes to accommodate a range of situations.

As prototypes they’re not the prettiest, but they’ll get the job done. Made with a laser-cut thermoplastic composite and 3M™ VHB™ Tape, Mach5 Tabs are lightweight, strong, and durable. Future versions will be die cut for a clean finish.

What are Tabs?

Connection points—aka fasteners, clips, notches—are diverse and include snap-on, screw-on, and push-in types. They’re essential for maintaining the integrity and alignment of vehicle parts, but many are made of plastic and tend to break with light impact.

Traditional fixes include cold welding, plastic welding, and epoxy resin—all of which are tedious and messy.

Our goal in creating Mach5 Tabs is to provide a straightforward, easy-to-install repair solution.

On this page

Join our Prototype Program

Want to help develop the newest Mach Five products?

Join our Prototype Program and receive a sample box of 25 tabs. Use them, test them, try to break them!

Your participation and feedback is invaluable to product improvement. Once you’ve tried our Mach5 Tabs we invite you to fill out our tester survey.

VIP Status

As a thank you for completing the survey you will receive VIP Status which includes:

Preferred pricing

Priority customer support

Mach Five merchandise discount

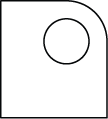

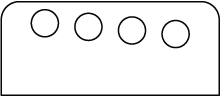

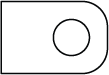

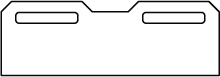

Mach5 Tab Types

| Tab A |  |

| Tab B |  |

| Tab C |  |

| Tab D |  |

| Tab E |

How to Use Mach5 Tabs

Disclaimer

Mach5 Tabs do not come with a warranty. These units have been distributed for the purpose of gathering feedback to improve product quality. Mach Five Motors is not liable for any damages or issues that may arise from the use of Mach5 Tabs.