Materials

Alloys

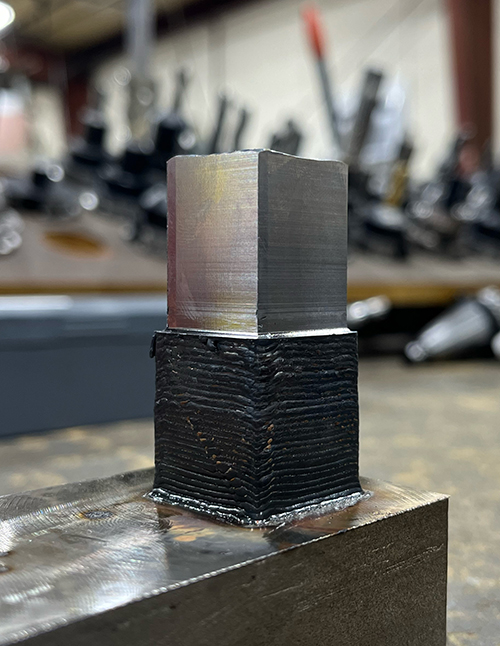

Alloy Composite™ Technology

Multi-Alloy

Multi-alloy integration via a proprietary wire-laser fusion method. Highly customizable, precise components with unique properties and functionality.

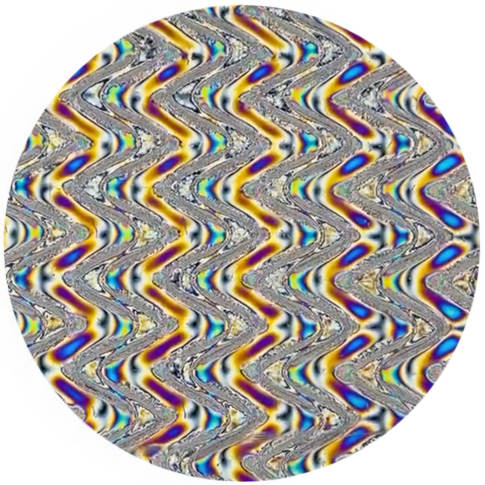

Polymers

Thermoplastic Composites

These polymer composites consist of long-strand, specifically-oriented fibers bound in a thermoplastic matrix. Lightweight, high strength, durable, sustainable, and corrosion resistant, thermoplastic composites are ideal when being light and strong are key requirements.

Methods

Hybrid Manufacturing

An advanced method combining additive and subtractive capabilities within a single system. Dual Wire Laser Metal Deposition (w-LMD) is paired with a 5-axis CNC for ultra-precise component fabrication of alloys and Alloy Composites

Laser vs Powder

In metal additive manufacturing, there are clear advantages to using laser over powder bed fusion. With w-LMD these include:

- Fully-dense parts

- Less material waste

- A larger build range

- Safer handling

- Multiple alloys within a single build

Thermoforming

Thermoplastic composite sheets are transformed into various shapes by applying heat, pressure, and molds. It’s a versatile process enabling the creation of a wide range of products with varying complexities.

Polymer 3D Printing

Ideal for lightweight components with complex geometries, with minimal material and energy usage. Industrial and commodity printers accommodate high-temperature thermoplastics, composite polymers, neat polymers, and metal-infused resins. Agile enough for rapid prototyping or finalized high-temp prints ready for annealing.

Proven Innovation

Mach Five Motors’ engineering pedigree rests on a solid foundation of R&D and commercialization in industrial solutions carried out across demanding industries

including aerospace, defense, energy, and transportation.

As a member of the Multiscale Group of companies, we are ideally situated to benefit from the collaborative atmosphere of research, product design, and manufacturing that the group offers. Together, we solve ambiguous, complex, or novel applications where practical experience is otherwise scare.

STANDARDS & COMPLIANCE

ISO 9001

AS9100

NIST 800-171

CMMC Level 2

Clear Composites™

National Institute of Standards and Technology

ArmorONE® Panels

Armory Technologies

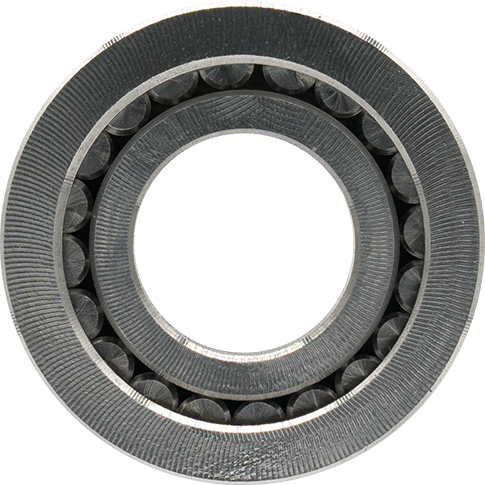

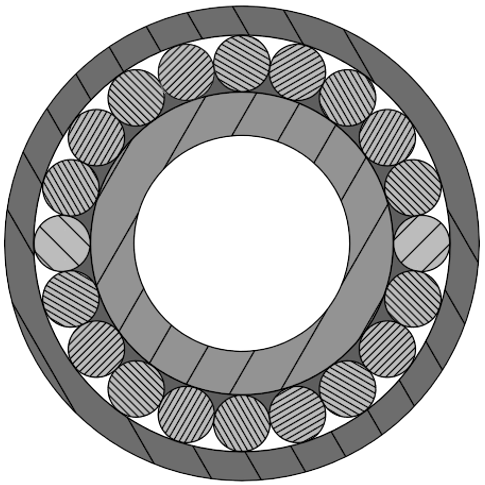

High-Performance Bearings

NASA

MetaTHERM® EGS

Department of Energy

Sodium Reactor Bearings

Proprietary